Harvesting Phase

The project begins for real!!!

After a long time in planning we are finally in the woods with enthusiastic volunteers.

With the weather forecast predicting rain by lunchtime fifteen volunteers arrived at a muddy Garston Woods near Sixpenny Handley, Dorset. The wood is managed by the RSPB and has been regularly coppiced for around 400 years!

Over a hot cup of tea the project outline was discussed, tool safety talks given and then work could begin.

With each volunteer being assigned a pair of loppers and a bow saw, they were quickly off harvesting hazel rods from the stools (the base of a coppiced) in our coup (the area of wood that is being felled). The cut rods were then divided into large and small diameters, tied into bundles and then stacked, ready for transporting to Old Sarum. By lunchtime drops of rain were beginning to fall but undeterred we carried on cutting and dragging until the end of the afternoon, when the rain properly arrived. After an rewarding day we are on track to have the harvesting phase finished in a couple of weeks.

28th

January

2013

January

2013

It was a close call with the weather this morning as the forecast was for heavy rain but, except for a shower at lunchtime, the rain held off all day.

With a second day of coppicing ahead it was some sore and aching bodies that arrived in the woods this morning. It is quite a physical job cutting and moving hazel and it was showing today, however a more efficient system of coppicing evolved as the volunteers found their feet.

As part of the project several flint axes have been made to give an idea of how the Neolithic people who constructed the houses at Durrington Walls would have harvested their materials. We unleashed the volunteers into the coup with various designs of axe and allowed them to get some experience of how different these tools are to use. For many this was the first time that they had used flint tools and it became apparent that they require a different technique to modern tools. Our aim is to gather a proportion of the materials used in this project using authentic tools, and this was just the start.

29th

January

2013

January

2013

30th

January

2013

January

2013

We met this morning in the Viking Longhouse at the Ancient Technology Centre.

After a cup of tea around the fire we were given a tour of the site with the emphasis on exploring the different building technology used and how the materials that will be collected in the next few weeks relate to the Neolithic House Project.

This was illustrated by showing how the coppiced hazel is used in a variety of ways, from making hurdles (lightweight and portable fencing panels) to constructing walls and fences. It helped bring into context all of the hard work of the last few days.

We returned to the woods for lunch and the afternoon was spent with saws and lopers in hand collecting larger hazel rods that are essential for the structural elements of the buildings, for example as wall stakes or rafters.

And finally the sun came out!

31st

January

2013

January

2013

The coup has become incredibly muddy after so much prolonged rain and it is hard to believe how you would have coped with these muddy conditions in the Stone Age. No grippy, steel toe capped boots in Neolithic times!

The focus of today was to continue with our use of flint tools to coppice the hazel in our coup. It was interesting to see how much time Neolithic people would have had to spend removing the enough material to make their houses.

We have had some breakages of our flint axes and it is now a question of whether our technique is lacking or whether our Neolithic ancestors had the same problems, and, if they did, were they all capable of repairing these axes when they were damaged.

1st

February

2013

February

2013

Its the end of the first week of the project and we are amazed at how much has been achieved. We are on track with our harvesting schedule and are confident that we will have all of the hazel that we need coppiced by the end of this phase of the project.

For the final day of this week we moved to another coup in the woods, unfortunately farther away from the car park. This did mean though that there was a longer, but very pleasant walk in. The hazel in this coup has been left for longer and therefore the rods that we were coppicing today were larger than we had all week. The straightest ones that we cut will probably be used as either wall stakes or rafters in the buildings.

An excellent week and everyone seems to have enjoyed their time in the woods.

4th

February

2013

February

2013

It is the start of our second week of coppicing and the enthusiasm was still evident when our volunteers arrived this morning, maybe the sunshine helped.

We continued where we left off last week, looking for larger rods to use in the main structure of the buildings.

Today, however, we intended to harvest the majority of the hazel with the flint axes and adzes that we have, which meant that we only used the bow saws and lopers to remove the shoots and branches on each rod (brash). This allowed us to gain a huge amount of practical experience using flint tools and also find their limitations, they don’t cut through wood quite as easily as steel tools! They tend to peel the wood along its fibres rather than cutting through which means that it takes considerably more blows to remove a hazel rod.

When you have spent a day of using these tools you certainly don’t need to visit the gym!

5th

February

2013

February

2013

Today we were back in our original coup to finish collecting the last of the small hazel rods.

Our volunteers didn’t look particularly surprised when the flint tools appeared again, we are wondering whether the excitement of using them is wearing off.

Over the last couple of days we have also been experimenting with copper and bronze axes, the buildings at Durrington Walls that we are reconstructing were built at the end of the Neolithic era. It soon became apparent that these axes with their sharp metal edges are more efficient at cutting wood and, given the chance, most of our volunteers preferred them.

This is our last day in this coup as we now have enough hazel rods to build with and it is amazing to think that a week ago you couldn’t see across the coup!

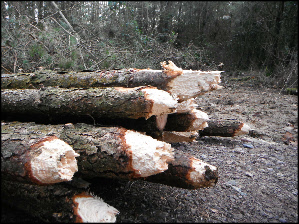

A Neolithic industrial landscape - coppiced hazel waiting to be taken to Old Sarum

Flint axes ready for use

Use damage to the edge of a copper axe

6th

February

2013

February

2013

We had more tool breakages yesterday. This time rather than the flint axe heads breaking, it was the handles. All of the flint axes that we are currently using have some kind of handle damage and so we gave the volunteers the day off to allow us time to repair them.

We managed to make two new hafts, one for our large axe head and also one for our adze. The axe haft is made from oak and the adze is made from field maple cut out of the woods on Tuesday.

These will be used next week when we hope to fell some larger trees to use as rafters and so this will be the last post until then.

Flint axe hafted with oak

Adze haft - before and after

14th

February

2013

February

2013

After a week away we returned to the woods with flint axes in hand.

Many of the axes had been repaired or re hafted and their edges honed in preparation for the task ahead.

The mission today was to cut down twenty larch trees. These trees were far more substantial than the hazel coppice, being about twelve years old but, because they are a soft wood, we wondered if they would be any easier.

The first signs were promising as the sound of flint axes striking trees echoed through the woods and large chippings littered the floor. It wasn’t long before the first tree crashed to the ground and from then on trees were harvested at a steady rate.

Tomorrow we move on to something larger!

Piled ready to go

The first one down

Trees to be cut

Volunteers in action

15th

February

2013

February

2013

We have moved up in size with todays task.

Armed with ten volunteers and four flint axes we headed back to the woods to fell a thirty metre high pine tree.

Today the volunteers chose the axe that they preferred rather than us insisting on them using a variety, as we felt it would be more productive for them to be comfortable with a particular tool. We felt that it was going to take a while and yesterday we had all estimated how long it would take to fell the tree and we had a range from thirty minutes to three hours.

It didn’t take long for the chips to start flying as we took turns chopping for two minutes each and by lunch time we had cut a large wedge out of the tree. We continued into the afternoon focusing now on the back cut to ensure that the tree fell where we wanted it, not where it wanted!

At 2.30pm, after a valiant effort by all involved, the tree started to creak and a few more blows later it fell. Cheers echoed round the wood, we had done it all with flint tools!

The total amount of blows struck was 11,477! We counted every one!

We have now reached the end of the harvesting phase and now all the materials will get delivered to Old Sarum for the construction phase to start at the beginning of March.

The tree to be felled

11,000 blows later

The successful team

The most popular axe in use